CNC Programming

- Overview

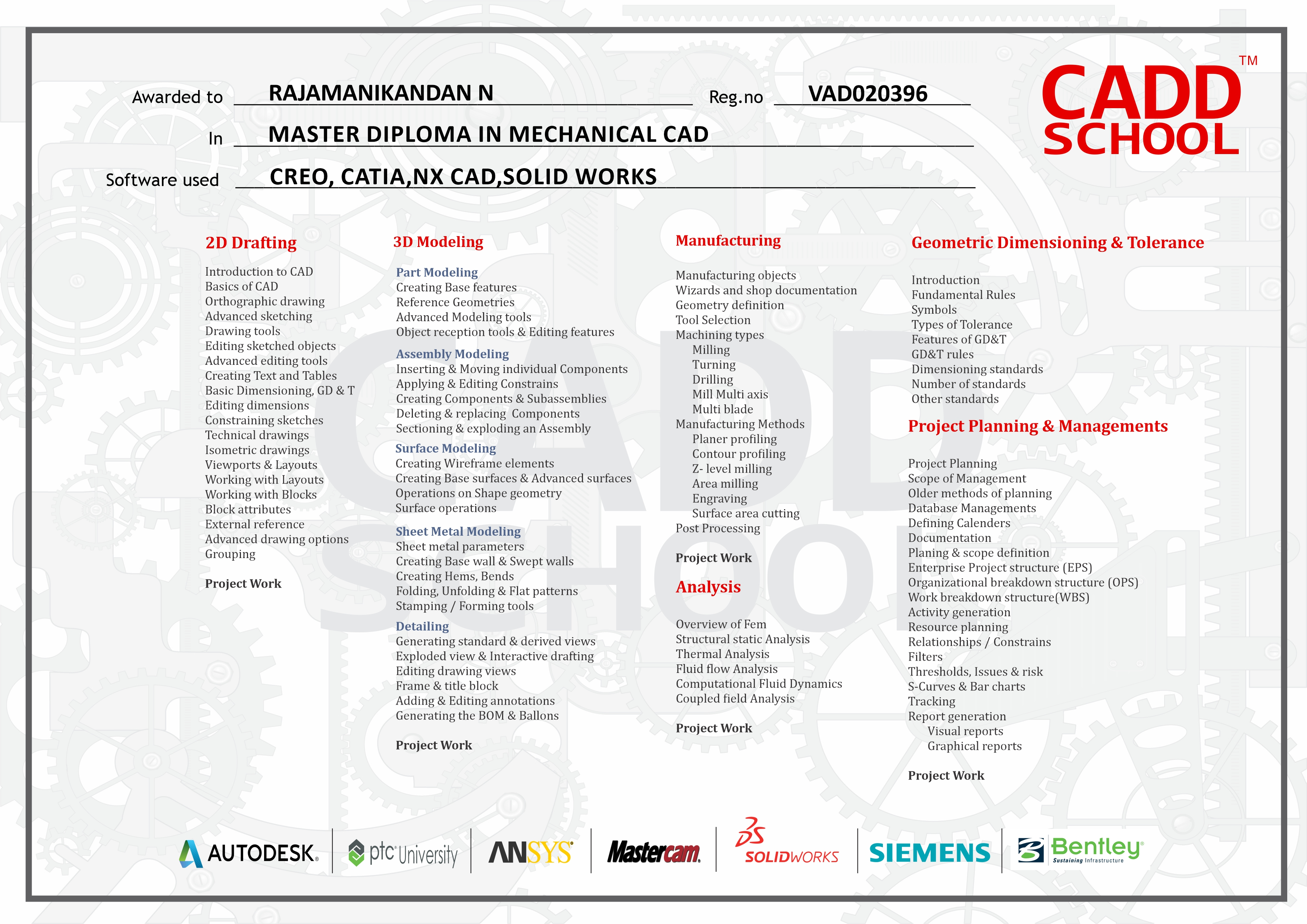

- Syllabus

- Course Material

- Duration

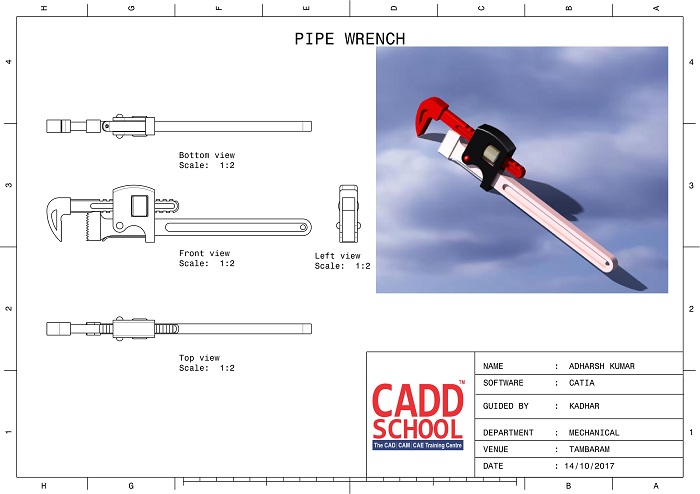

- Projects

- Certifications

CNC programming (Computer Numerical Control Programming) is utilized by manufacturers to create program instructions for computers to control a machine tool.

CNC is highly involved in the manufacturing process and improves automation as well as flexibility.

CNC programmers write instructions for CNC machines, where a computer is connected to the mill, along with electrical drives and sensors for a complete system, This computer controls the movement of the machine axis.

Generally there is one international standard—ISO 6983. G-code (also RS-274), which has many variants, is the common name for the most widely used numerical control (NC) programming language.

It is used mainly in computer-aided manufacturing to control automated machine tools.

Syllabus

Introduction About Manufacturing

Evolution of NC

Geometric Dimension & Tolerance

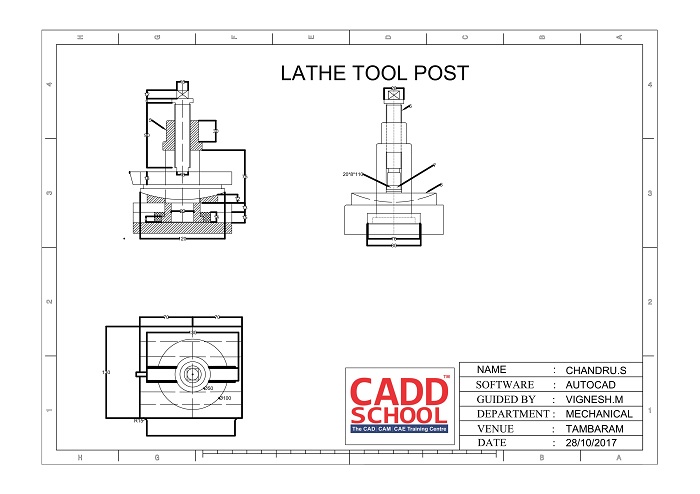

Basic 2d Geometry Creation-1

Basic 2d Geometry Creation-2

Basic 2d Geometry Creation-3

Basic 2d Geometry Creation-4

Basic 2d Geometry Creation-5

Contour Milling Operation-1

Contour Milling Operation-2

Z Level Milling Operation

Surface Contour Milling Operation-1

Surface Contour Milling Operation-2

Surface Contour Milling Operation-3

Radial Cut Operation

Drilling Operation-1

Drilling Operation-2

Drilling Operation-3

Turning Operation-1

Turning Operation-2

Turning Drill Operation-1

Turning Drill Operation-2

Turning Drill Operation-3

Turning Drill Operation-4

Turning Drill Operation-5

Multi Axis Operation -1

Multi Axis Operation -2

Duration

100 Hours + Project Training

Enquiry

MECHANICAL COURSES